BucketEars - How To Fiberglass Your Puddle Duck

The face of the plywood is naturally impervious to water and you really only need latex paint to make it waterproof. Just like the plywood my house is made of it simply has a couple of coats of latex paint to keep the rain out. The edges of plywood are a completely different story and have issues. They act sort of like a straw and will pull water into the laminations. It is a really good idea to fiberglass all of the outside edges of your pdracer to seal the edges this also greatly increases the strength of those joints. If you have never done it before you may be intimidated but it really is very simple and easy. Basically it is just like paper machet only instead of using a white glue and newspaper you use epoxy and fiberglass cloth.

Safety:

There is a bunch of spooky stuff written about using epoxy on the internet so to absolve my self from liability I'll just tell it to you like this: Epoxy is poisonous and will kill you. You should not use it. Some people are allergic to it and some people can quickly develop an allergy to it if not handled properly. The info on this page is just what I do. I suggest that if you are going to do epoxy work read elsewhere how to do it properly. I always have a fan going have the garage door open wear gloves face mast safety goggles apron and have a tub of vinegar.

If you get epoxy on your skin vinegar will dissolve un-cured epoxy and help you get it off your skin.

Epoxy

There are various epoxies that you can get the biggest difference between them is their mixing ratios. The stuff I use mixes at 2:1 ratio and works great. I've got repairs and other things I did with epoxy that has been out in the weather for years and it is still holding fine today.

The important part you will want specified is "no blush". That means as it cures it won't make an oily surface. You will need about a quart to do a duck. I buy it in the 1.5 gallon kits because I do lots of glass work and it has a really long shelf life. I have used epoxy that I personally knew was 30+ years old and it worked fine.

There is some other hype that various epoxy vendors will assert about their epoxy but realistically almost all epoxy is the same and the job we are asking it to do is fairly easy so as long as it is "no blush" epoxy I am sure it will work just fine.

Epoxy VS Polyester Resin

Polyester resin is commonly available in local hardware stores you can recognize it because it will be a large amount of resin that comes with a tiny tube (like less than an ounce) of Methyl Ethyl Keytone (MEK) activator to cure it. Epoxy comes in two large resin containers and is activated by mixing the two resins.

I do not suggest using polyester resin it does not stick very well to anything except itself and is incredibly stinky when curing. Over time I have seen polyester resin release from plywood partly from flexing and partly from moisture due to it's poor adhesive qualities.

MAS 1 Gallon Epoxy Kit

AeroMarine Epoxy Resin 1.5 Quart Kit

Fiberglass cloth tape 4" - 6 ounce cloth

Fiberglass Cloth Tape, 6 oz, 2" Wide by 50 Yards

4" fiberglass tape

It is fiberglass cloth that comes in a long narrow ribbon and does NOT have adhesive. It is usually specified such as "4 inch 6 ounce" and the "6 ounce" part is the thickness of the cloth. So 4 ounce cloth is really light and 9 ounce more than twice as thick. Fiberglass tape has a nice loose weave to it so it is easy to get it to conform to rounded corners.

You can typically order it by the length needed or buy it in rolls. If you want to order by length and only get the minimum you should measure the length of every seam you want to cover and then get twice as much as you think you need. That way if you screw up you have extra. Because I build a lot of boats and other stuff I get two full 50 yard rolls every time I order. When I get down one roll I'll order another pair of rolls. Fiberglass cloth lasts forever and after you start glassing you will do other repairs with this cloth.

If you want to make a DIY set of oars using plywood blades it really helps make the oars last longer if you fiberglass the edges of the blades. A household related project that I fiberglassed is I have a plywood cabinet on my back porch that I keep pool supplies in -- I glassed all the edges on it to make it stand up better to the weather. Lots of other projects like that.

I do not suggest drywall fiberglass from home improvement stores that stuff is very open weave is very stiff and does not bend around corners very easily.

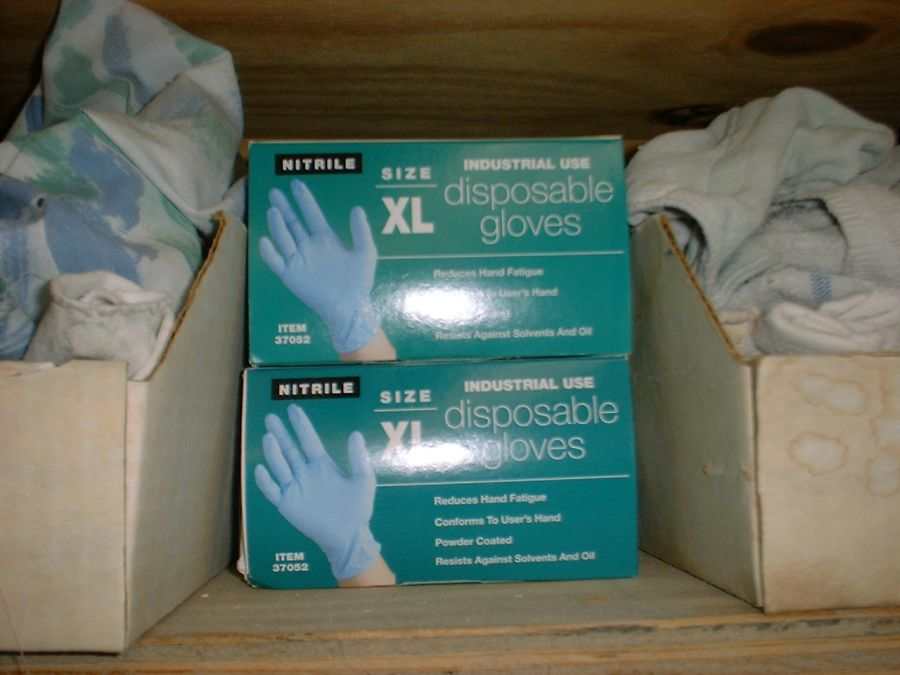

gloves

I prefer nitril gloves and always have two boxes in my workshop. I use a couple of pairs as I glass stuff like if I have to scratch my nose I can just take one off and throw it away scratch then pull on a fresh glove. They are cheap enough that you can treat them like that. I have found that latex gloves are kind of wimpy and will sometimes break right in the middle of applying glass.

paper towels

I am not joking you need a paper towel dispenser in your workshop.Prepare the chines and edges

You will be infusing the fiberglass cloth with epoxy which makes the cloth sticky and then laying it around the outside edges of your boat. The cloth has a difficult time sticking to a sharp 90 degree corner so you want sand and round all the edges you are going to glass. I use a sanding disk in my drill but others use belt sanders routers or other methods. Whatever you do try and get a nice even rounded corner. The smoother the corner you get the easier it will be to put your glass over it and not end up with an air bubble.

Prepare lengths of fiberglass cloth

I prefer to apply multiple smaller sections of glass instead of trying to apply the entire chine at one time. So what I do is make a bunch of 24" lengths of cloth and also the smaller pieces that will go on each of the transom corners. Some people use a big sheet of cardboard to layout their pieces of glass but I do enough of this type work that I have a big plastic tub that I stage my fiberglass strips in.

Pencil Line Tip: When your hull is finished after painted you will be able to see the fiberglass cloth along the edges of your duck specifically the sides will be most visible. One trick to make it neat looking is to draw a pencil line along the sides just up from the chines. Then when applying your fiberglass try to align one edge along that pencil line. Because of the weave of the fiberglass cloth the other side of the tape will be more wavy but that side ends up being on the bottom of the boat where not very many people look.

Mixing Your Epoxy

Depending on what type of epoxy you get it needs to be mixed in a certain ratio. Refer to the data sheet that comes with your epoxy which will list both a weight and volume specification to tell you how to mix your epoxy properly.

There are lots of ways that people measure epoxy some use special hand pumps and count the number of squirts some use postal scales and weigh their epoxy. I have seen asymetrical balance scales that have 2 cups on them and when each cup has the proper amount of resin the scale balances and you then mix those two cups together. Another method a friend of mine does his wife is a nurse and brings home these super cool disposable measuring cups that have a scale on the side.

This is the method I prefer to use when mixing my epoxy I mark a popsicle stick with the ratio of each component and then fill up to their respective lines. Then I use that same stick to stir and mix the epoxy.

Example:

Lets say I am doing a very small glass area

and I am using 2:1 epoxy.

I'll mark my stick at 1/4"

and then at 3/4".

Then I add in the 1 part stuff to the first mark

and the 2 part stuff fills up to the 2nd mark.

That way I end up with the right ratio of 2:1.

So if I am doing a bigger batch

I'll mark the stick at 1"

and then again at 3"

and so on.

Next I stir like crazy.

As you stir

you will see swirls appear in the fluid.

Then after a bunch more stirring

the swirls go away and the epoxy is mixed pretty good at that point.

Most problems with epoxy are either not having the right mix ratio

or not stirring properly.

I do atleast 50 turns in that cup

but a lot of times I do more.

NOTE: I try to only mix up small amounts of epoxy and mix more as needed. Because I use disposable gloves it is very simple when I run out of epoxy but still have more glass to lay down. I simply grab a paper towel use it to pull off and throw away my gloves then I put on some new gloves and mix up another batch of epoxy and continue working. Throwing away a few gloves and paper towels is a lot cheaper than mixing too much epoxy and not using it.

How to apply fiberglass cloth

I don't have any pictures of me applying glass because I usually work alone

and my hands are covered in epoxy.

The picture to the right shows what the chines look like after the epoxy and fiberglass has been applied.

Here is how it goes:

- I put the cloth in a bucket or plastic tub and then pour a little epoxy on it

- I spread the epoxy over the cloth with my (gloved) fingers

- After the cloth is fully wet I pick it up and gently pull it through my hand while lightly squeezing to get the excess epoxy off the cloth

- I lay the wet glass on the target area

- smooth out and use a squeegee or paint brush to remove the air bubbles. I sometimes use an epoxy roller

- if the cloth looks too dry I'll apply a little more epoxy to the surface with a paint brush

Clean Up

Vinegar will dissolve uncured epoxy so if you get some on your skin or want to clean off your tools you can use vinegar to do that.

After you learn how easy it is to use fiberglass and epoxy you can do all sorts of repairs to your boat. I punched a big hole in the bottom of my duck. One day when I was out sailing the wind kicked up to 50 mph so I came in for a crash landing on a rocky beach to sit out the weather and landed on a rock which punctured my hull.

I always carry a sponge or super-shami (fancy rag) to mop up spray water that lands in the cockpit. To fix the hull for the ride home I just stuffed the shami rag in there and it plugged the hole just fine while sailing back to the dock.

The picture to the right is after I had done some sanding to the hole and was just about to glass over it. Here is more info about repairing that hole in the hull

Here is another fun thing I did with epoxy.

After a few years

the cockpit sole of my duck was getting a bit splintery because I used cheap pine plywood

plus I live in the desert and was storing the hull outside

uncovered.

I sanded the sole

then epoxied a bedsheet to the inside of the cockpit and it works great.

Made a nice smooth surface

but was cheaper than using fiberglass cloth.

Some more fiberglass projects:

Fiberglass PDRacer Mast Sleeve

Fiberglass Holder 12 Sailboat

Fiberglass Old Laser II Sailboat Hull

Fiberglass Mast Sleeve Laser II Sailboat Hull