ECDuck - The Build Continues 2

By Scott Widmier

Hi Shorty,

The build is moving along despite a sticky mistake today. Sticky because I tried to be economical and use old epoxy hardener that I found in the bottom of a jug I was cutting up to use as a mixing bowl. A couple of hours later I found myself disassembling and scraping off sticky goo. Been there and done that even though I know being economical can costs more time and labor in the long run. I did get the mast step installed (everything under the deck) and glued up both 42" by 9" leeboards butcher block fashion. I am going with long and narrow foil shapes in the hopes of better windward performance though some are trying to talk me into short and fat for shallow water. I will probably test out a short and fat and, if decent, may carry one onboard just for Florida Bay. I have been trying to decide on putting in some 8" deckplates for access into the side airboxes. On one hand the access to a little more storage is welcome but I really don't want to be tempted into sailing with those things open.

I also have been working with my design team on the auxiliary propulsion system for the boat. I don't think any of us expects a lot of speed, but something that can be peddled while the boat is being sailed will help to windward and move the boat when I have to take the mast down. We are designing a fish tail system and I have included some drawings so you can follow along. First one shows the duck from the top with the central deck peeled away. In one of those wonderful little accidents, I discovered my pivot bolts, which go all of the way through the airboxes for ruggedness, are also perfectly located to hang some bicycle cranks and pedals on. I have an extra bike or two cluttering up the garage! Lines would be attached at the end of these crankshafts near the peddles and run back through one set of fairleads or pulleys to the crossbar on the end of the shaft for the drive system. Pulling the lines would have the effect of raising the peddles up an out of the way should I need more room for sleep.

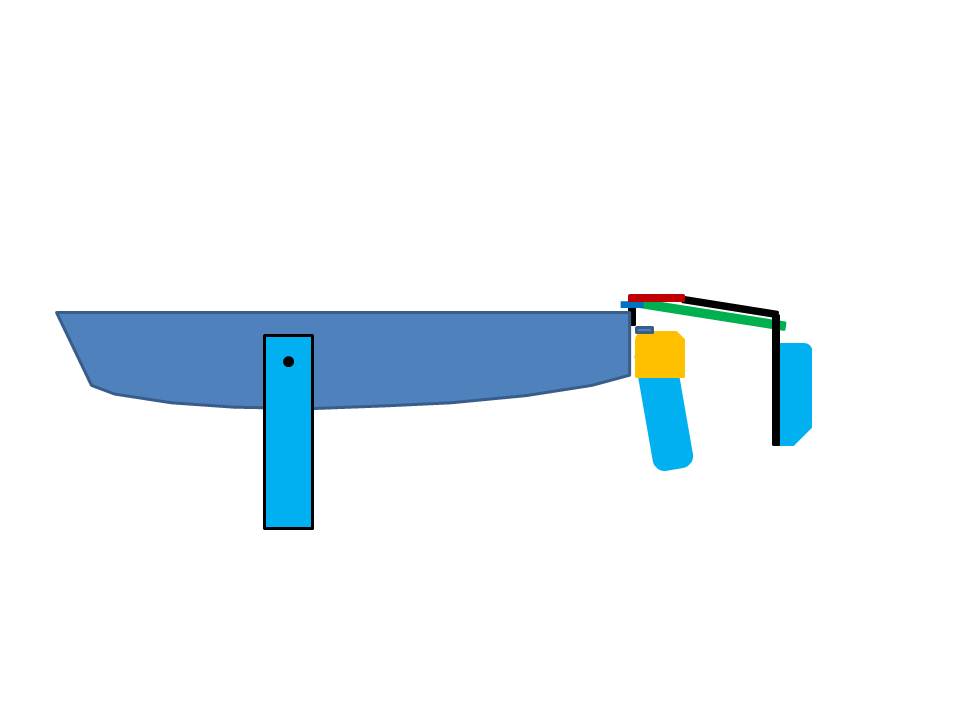

The T bar style shaft for the drive will be attached to the boat via an oarlock (KISS) allowing for easy removal. It won't be in the way of the rudder as the rudder will be hung below the top edge of the transom with the control lines going through the transom and into the boat. At the end of the T bar shaft will be the pivot point for a second arm of the drive. This arm will extend either side of the pivot point with one being attached to the T bar with heavy duty rubber or shockcord and the other supporting the drive fin. The shockcord will give the system the whipping force at the end of each stroke. The fin will be made of lexan plastic (supposedly unbreakable) which has a nice flex itself. This will be attached to a 3/4" aluminum shaft using stainless steel bimini hardware (have some in my inventory). The shaft will be attached to the drive arm by a horizontal bolt and held down by shock cord so it can kick up if the boat grounds. I will also have a line to raise the fin clear of the water should I want to reduce resistance.

The drive will induce lateral moment to the boat which will be resisted by the leeboard and the rudder (similar do the dorsal fins on fish). I will need to have a leeboard and rudder deployed to use the system. For shoal water work I plan on bringing a pushpole.

Scott