A Test of Different Paints and Finishes

By Phil Keck #39 "S.S. Pubert" (5ar)In my travels across all of the different boatbuilding sites around, I've found that finishes are one of those topics that everyone has a different opinion on. Paint, varnish, epoxy, polyester, blah blah blah… everyone has their personal favorite, but I never found any websites that had actual data to back up their opinions. I've mooched lots of free information from the boatbuilding community, so I thought this might be my chance to give a little back.

I performed a semi-long term test of two oil based varnishes (Minwax Helmsman Spar Urethane from Home Depot and Varathane from Menard's), one water based polyurethane (Poly Finish from Home Depot), and some gloss red Rust-o-leum.

The general idea was that I'd cut up some scrap pieces of wood, apply some different finishes, weigh them, soak them in water for a while, then weigh them again, then soak them, then weigh them….on and on. If any water was getting through, the mass would go up. Pretty simple, eh? If you just want to see the results, skip to the excel file.

Preparation

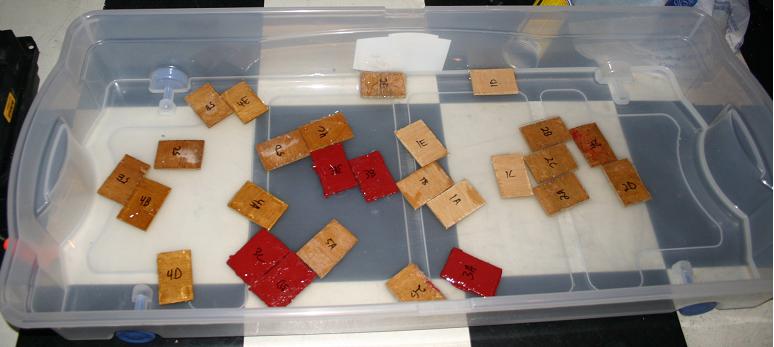

A large scrap piece of 5.2 mm 3-ply lauan from Home Depot was cut into ~2"x3" rectangles. 5 of these rectangles would remain unfinished and act as controls; 5 rectangles would receive three coats on all sides of Home Depot varnish; 5 rectangles with Menard's/Varathane varnish; 5 rectangles with water based poly; and 5 rectangles with Rust-o-leum. Here are some of the pieces before being finished.

To apply the finish, I set each group of 5 down on a piece of pink foam. I then used an old rag to apply the finish to the face and all four sides of each piece. Each type of finish got its own rag, and I used a new rag for each new coat (what can I say, I have a lot of old t-shirts that I've cut up). The pieces were sanded with 180 grit sandpaper and wiped clean with a tack cloth between coats.

Here's an image of the 5 Rust-o-leum pieces with a fresh coat applied.

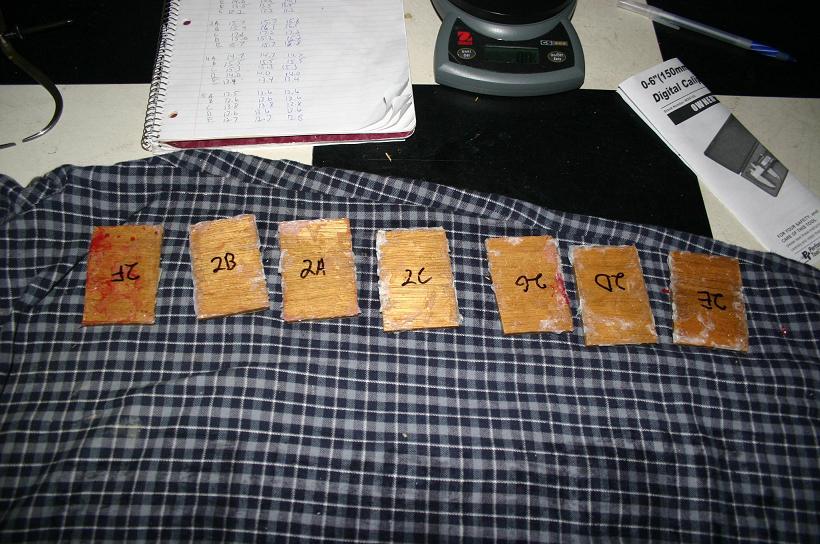

Here are the water based poly pieces. You'll notice that I actually ended up with seven pieces of these…I cut a few extra rectangles, and figured I'd use them, so here they are.

Note: The Menard's/Varathane varnish had something wrong with it. It had this thick brown paste that had settled to the bottom, and no amount of mixing with a stick or with my fingers mashing it up could get it to go away. I ended up using the liquid that remained on top for this test. I have no idea if this affected the results positively or negatively.

The finishes were applied in my garage, and the temperature ranged from about 75 degrees F up to about 85 degrees F. Each coat was allowed to dry for about 24 hours, as I wanted to minimize the possibility that there was incomplete drying/curing.

After I applied the first three coats, I flipped them over and applied three coats to the back face. I also applied these coats to the sides of the pieces, so the sides ended up with 6 coats of finish, and the faces got 3 each.

After all coats of finish had been applied, I labeled the pieces as follows:

1A-1E: No Finish

2A-2G: Water-based Poly

3A-3E: Rust-o-leum

4A-4E: Minwax Varnish

5A-5E: Menard's/Varathane Varnish

A quick side note…I was curious about how thick this plywood actually was, so I got out the calipers and measured two of the pieces prior to finishing. It turns out that the lauan ply is a little thicker than advertised…or at least the pieces I had were. Yes, this information is probably completely useless, but I figured I'd throw it in there in case anyone was in need of useless trivia.

Testing

Each piece was weighed to determine the starting mass of the piece plus the finish. I used an Ohaus scale that measures out to 0.1g. Here you can see piece 1A: no finish.

Once I got the mass of all of the test pieces, I threw them into a tub of water and pushed them down so that the top of each piece was wet.

Measuring

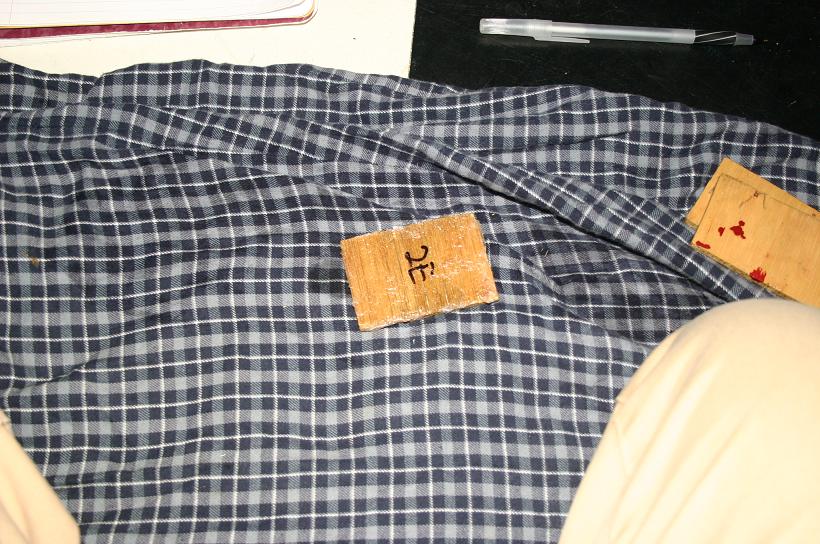

I came back an hour later and pulled the pieces out to dry them off. I didn't want there to be any water on the surfaces of the pieces….all I wanted to know about was the water that had migrated into the finish or into the wood. So I first wiped each piece off with some scrap flannel cloth that I had…

…and then wiped each piece off with fresh paper towel until they were completely dry. After being dried on the flannel and paper towel, each piece was again placed on the scale to determine the mass.

Here's a picture of the Rust-o-leum drying. Once I had the mass of each of the pieces, I threw them all back in the water. I added water to the tub every couple of days to make sure it didn't dry out. I recorded the mass of each piece at 1 hour after initially going in the water, 2 hours, 3 hours, 4 hours, 5 hours, 13 hours, 71.5 hours, 95 hours, and then approximately 672 hours after going in the water.

Results

The attached excel file has all of the details of how the mass went up with each finish. The unfinished pieces gained the most mass, as expected. On average, they gained 9.4 grams of water over the ~3 weeks of soaking. They rapidly gained weight in the beginning, and then weight gain slowed down. I assume this is because the wood was reaching the fiber saturation point. Once it's soaked, it ain't gonna get soaked no more.

The Minwax Varnish pieces gained the least mass (1.8 grams over 3 weeks). Most people say that varnish is an excellent finish, and this test agrees with that. The Menard's/Varathane Varnish went up more than the Minwax stuff (6.5 grams over 3 weeks), but I'd be willing to bet that it has something to do with that goop that was at the bottom of the can. I should do the test again with a different can of their stuff. I also wonder if there was some delamination that was too small to see. The rate of mass gain in the Varathane increased pretty suddenly in all of the pieces toward the end, and this would indicate that something was happening other than water migrating through the finish.

One of the pieces of wood that had been finished with the Minwax varnish delaminated. The bottom piece in this picture is fine, but you can see in the top piece that the top layer of ply has delaminated from the core layer. The delaminated piece gained a lot of mass, and this is to be expected. I excluded this piece from the final results.

The Rust-o-leum was a real shocker. I used that stuff on my Puddle Duck, and it's held up really well. I figured this meant that it sealed the wood as good as anything, but that apparently isn't the case (they gained 6.6 grams over three weeks). I've heard that latex paints don't bubble as much as other types of finish because they allow water to pass through them more freely, and the test results here agree with that.

Another surprise result came from the water based polyurethane. I had read that these finishes don't seal the wood very well, but it worked almost as well as the oil based varnish (3.3 grams gained over three weeks). The only problem I saw with the water based stuff was that it got cloudy in spots. When I applied the finishes, it got kind of goopy in places because the wood was sitting flat on the pink foam. So instead of a smooth, even finish, I got these lumpy spots. The lumpy spots were where the poly got cloudy and white. If the finish were applied more carefully, I bet it wouldn't be a problem.

Anyhow, those are the results! Far from comprehensive, but it provided some interesting information, none the less.